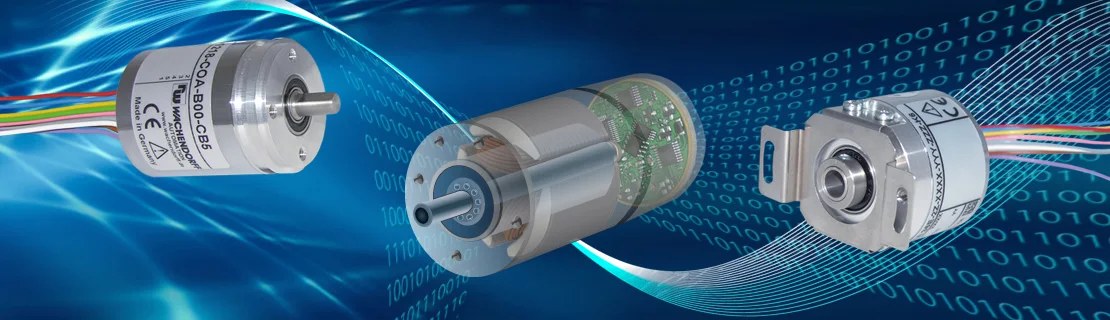

Motor Feedback of the Latest Generation

- With EnDra®, no battery and no gears

- Wide temperature range from -40 °C to +85 °C (+105 °C on request)

- The highest dynamics (50µs) and accuracy (0.09°) in a magnetic system

- Very small and compact design

- High reliability

- Complete encoder or installation set

- Singleturn / multiturn

- Possible interfaces for the motor circuit board: SSI, CANopen

With a high 16-bit singleturn resolution and 43-bit multiturn, installation solutions are ideal for applications which are dependent on mechanical robustness and high accuracy. The interface submits the complete position value for evaluation.

The singleturn position resolution for 16 bit is 65.536 steps per revolution. Depending on requirements, multiturn can resolve up to 43 bit.

The maintenance-free installation solutions can manage without a gearbox and back-up battery This ensures that the mechanics have a high durability and they are environmentally-friendly — Thanks to EnDra®.

The function principle of EnDra® technology:

Wachendorff WDGA installation solutions do not require a mechanical gearbox to record the number of revolutions and the direction of rotation. Instead, the revolutions are determined by an energy wire (EnDra®): A permanent magnet accumulates so much energy in the wire that ‘revolution’ and ‘direction of rotation’ information is transferred to the evaluation electronics at a defined position. An external energy supply e.g. via battery, is not required for this. As a result, the system works in a way that is fully independent, with no need for maintenance.

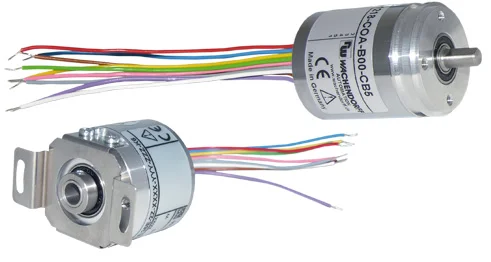

1. A ready-to-use rotary encoder (plug and play)

The WDGA36A Closed Absolute Encoder or WDGA36E Closed End Hollow Shaft Encoder can be acquired from Wachendorff as a ready-to-use solution. With their 36 mm casings, the encoders are extremely compact. The encoder is directly assembled in the motor or on the motor shaft and connected to the motor circuit board via a cable. It is no longer required to start up the encoder separately in the motor. The encoder is ready-to-use instantly.

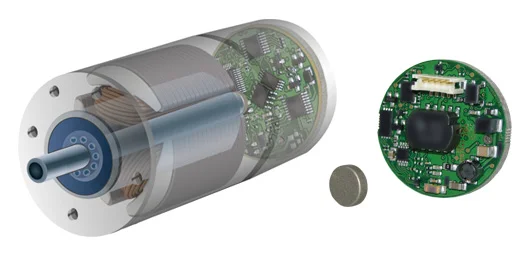

2. Installation set (WDGA circuit board and magnet)

The installation set for the motor assembly, consists of a single/multiturn circuit board and the appropriate magnets. The motor function was designed to be electric, inductive and mechanic with this set. For instance, mechanical shielding in the motor takes place via an iron casing. The mass production commissioning requirements are defined by the client.

Wachendorff can provide support with many years of expertise. We can offer installation as a complete service for assembly and commissioning or we can advise you.

A complete service:

The WDGA circuit board and the magnet are assembled and calibrated in the motor by Wachendorff. This means that the motor is delivered to Wachendorff as a customer-provided component. After assembly, we deliver the motor with a calibrated encoder for end commissioning.

You can do everything yourself:

Wachendorff provides you with the circuit board and magnets. Installation and calibration take place in your workflow. Wachendorff can advise and support you in planning and calibrating your final testing station.

| Technical data | |

|---|---|

| Temperature range: | -40 °C up to +85 °C (+105 °C on request) |

| On-board interface: | a choice of SSI or CANopen, on request: BiSS-C and others |

| Single turn resolution: | max. 16 bit |

| Overall multi turn resolution: | up to (16 + 43) bit |

| Accuracy: | ±0.09° |

| Dynamics: | 50 µsec |

| Supply voltage: | 4.75 VDC up to 32 VDC |

| Dimensions(HxD): | |

WDGA36E-K6: WDGA36A-K6: WDGA installation set: | 37.1 mm x 36 mm 32 mm x 36 mm 4.7 mm x 33 mm |